Two cycle Engine

Applications and Lubrication Needs

The best two cycle engine oil

FREE Amsoil catalog

Two cycle engines can be found nearly everywhere these days. They are used in dozens of applications and in a wide variety of designs for everything from work and recreation to power generation. two cycle engines have design differences and operate under conditions that require different oil chemistries than their four-cycle counterparts. In order to recommend a lubricant for a two-cycle engine, one needs to know how this engine operates, why it is used in place of a four-cycle engine and where and in what type of applications it is used.

Two cycle Engine

What is a two cycle engine? How do two cycle engines work?

Two cycle engine

The terms “two-cycle” and “two-stroke” are often inter-changed when speaking about two cycle engines. These engines derive their name from the amount of directional changes that the pistons make during each power stroke. Internal combustion engines are used to produce mechanical power from the chemical energy contained in hydrocarbon fuels. The power-producing part of the motor’s operating cycle starts inside the motor’s cylinders with a compression process. Following this compression, the burning of the fuel-air mixture then releases the fuel’s chemical energy and produces high-temperature, high-pressure combustion products. These gases then expand within each cylinder and transfer work to the piston. Thus, as the engine is operated continuously, mechanical power is produced. Each upward or downward movement of the piston is called a stroke. There are two commonly used internal combustion engine cycles: the two-stroke cycle (Two cycle engine) and the four-stroke cycle.

Two cycle Engine

How are two cycle engines different from four-cycle engines?

Two cycle engine

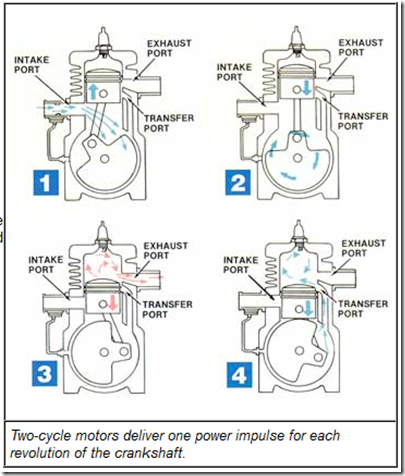

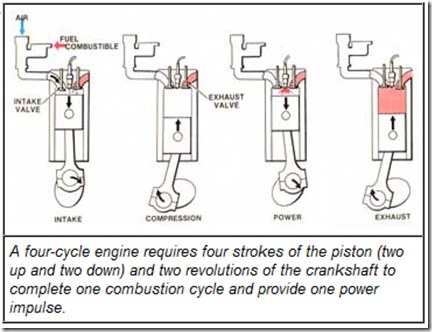

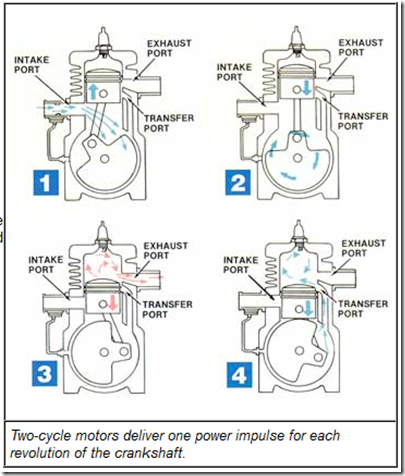

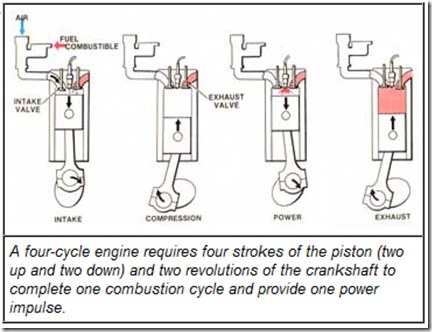

The fundamental difference between two cycle engines and four-cycle engines is in their gas exchange process, or more simply, the removal of the burned gases at the end of each expansion process and the induction of a fresh mixture for the next cycle. The two cycle engine has an expansion, or power stroke, in each cylinder during each revolution of the crankshaft. The exhaust and the charging processes occur simultaneously as the piston moves through its lowest or bottom center position.

In a four-cycle engine, the burned gasses are first displaced by the piston during an upward stroke, and then a fresh charge enters the cylinder during the following downward stroke. This means that four-cycle engines require two complete turns of the crankshaft to make a power stroke, versus the single turn necessary in a two-cycle engine. In other words, two-cycle engines operate on 360 degrees of crankshaft rotation, whereas four-cycle engines operate on 720 degrees of crankshaft rotation.

Where are two cycle engines used?

Two-cycle engines are inexpensive to build and operate when compared to four-cycle engines. They are lighter in weight and they can also produce a higher power-to-weight ratio. For these reasons, two-cycle engines are very useful in applications such as chainsaws, Weedeaters, outboards, lawnmowers and motorcycles, to name just a few. Two-cycle engines are also easier to start in cold temperatures. Part of this may be due to their design and the lack of an oil sump. This is a reason why these engines are also commonly used in snowmobiles and snow blowers.

Some advantages and disadvantages of two-cycle engines

Because two-cycle engines can effectively double the number of power strokes per unit time when compared to four-cycle engines, power output is increased. However, it does not increase by a factor of two. The outputs of two-cycle engines range from only 20 to 60 percent above those of equivalent-size four-cycle units. This lower than expected increase is a result of the poorer than ideal charging efficiency, or in other words, incomplete filling of the cylinder volume with fresh fuel and air. There is also a major disadvantage in this power transfer scenario. The higher frequency of combustion events in the two-cycle engine results in higher average heat transfer rates from the hot burned gases to the motor’s combustion chamber walls. Higher temperatures and higher thermal stresses in the cylinder head (especially on the piston crown) result. Traditional two-cycle engines are also not highly efficient because a scavenging effect allows up to 30 percent of the unburned fuel/oil mixture into the exhaust. In addition, a portion of the exhaust gas remains in the combustion chamber during the cycle. These inefficiencies contribute to the power loss when compared to four-cycle engines and explains why two-cycle engines can achieve only up to 60 percent more power.

How are two-cycle engines lubricated?

Two-cycle motors are considered total-loss type lubricating systems. Because the crankcase is part of the intake process, it cannot act as an oil sump as is found on four-cycle engines. Lubricating traditional two-cycle engines is done by mixing the oil with the fuel. The oil is burned upon combustion of the air/fuel mixture. Direct Injection engines are different because the fuel is directly injected into the combustion chamber while the oil is injected directly into the crankcase. This process is efficient because the fuel is injected after the exhaust port closes, and therefore more complete combustion of fuel occurs and more power is developed. Direct injection engines have a higher power density than traditional two-cycle engines. Because the oil is directly injected into the crankcase, less oil is necessary and lower oil consumption results (80:1 range). Direct Injection motors have higher combustion temperatures, often up to 120F. They also require more lubricity than traditional two-cycle motors.

Amsoil Dominator

WordPress Tags: cycle,Engine,Lubrication,Needs,recreation,generation,lubricant,Internal,combustion,chemical,energy,compression,mixture,temperature,products,cylinder,Thus,movement,difference,removal,expansion,induction,revolution,bottom,words,rotation,Where,ratio,Weedeaters,Part,Some,advantages,unit,output,factor,size,result,efficiency,disadvantage,scenario,frequency,events,results,rates,chamber,walls,Higher,Traditional,addition,portion,intake,Direct,Injection,port,consumption,differences,counterparts,cylinders,cycles,degrees,temperatures,disadvantages,outputs,units,systems,engines,four,piston,crankshaft,sump,motors,crankcase