What Is Lubrication?

Read the whole story on Machinery Lubrication here.

Get your Free Amsoil catalog here.

Wes Cash, Noria Corporation

Tags: industrial lubricants, synthetic lubricants, greases

Lubrication is a word that’s often used in regards to machinery reliability and maintenance, but what is lubrication? The dictionary defines lubrication as the application of some oily or greasy substance in order to diminish friction. Although this is a valid definition, it fails to realize all that lubrication actually achieves.

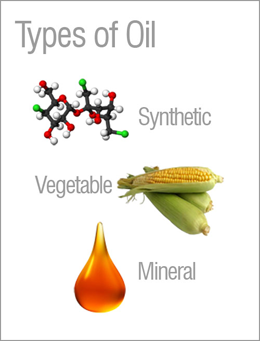

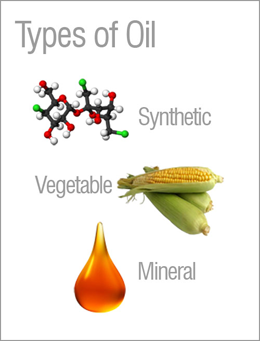

Many different substances can be used to lubricate a surface. Oil and grease are the most common. Grease is composed of oil and a thickening agent to obtain its consistency, while the oil is what actually lubricates. Oils can be synthetic, vegetable or mineral-based as well as a combination of these. The application determines which oil, commonly referred to as the base oil, should be used. In extreme conditions, synthetic oils can be beneficial. Where the environment is of concern, vegetable base oils may be utilized.

WordPress Tags: Lubrication,word,machinery,maintenance,dictionary,substance,friction,Although,definition,Many,Grease,agent,consistency,mineral,combination,Where,environment,substances,vegetable

Lubricants containing oil have additives that enhance, add or suppress properties within the base oil. The amount of additives depends on the type of oil and the application for which it will be used. For instance, engine oil might have a dispersant added. A dispersant keeps insoluble matter conglomerated together to be removed by the filter upon circulation. In environments that undergo extremes in temperature, from cold to hot, a viscosity index (VI) improver may be added. These additives are long organic molecules that stay bunched together in cold conditions and unravel in hotter environments. This process changes the oil’s viscosity and allows it to flow better in cold conditions while still maintaining its high-temperature properties. The only problem with additives is that they can be depleted, and in order to restore them back to sufficient levels, generally the oil volume must be replaced.

Reducing friction is a key objective of lubrication, but there are many other benefits of this process. Lubricating films can help prevent corrosion by protecting the surface from water and other corrosive substances. In addition, they play an important role in controlling contamination within systems. The lubricant works as a conduit in which it transports contaminants to filters to be removed. These fluids also aid in temperature control by absorbing heat from surfaces and transferring it to a point of lower temperature where it can be dissipated.

Reducing friction is a key objective of lubrication, but there are many other benefits of this process. Lubricating films can help prevent corrosion by protecting the surface from water and other corrosive substances. In addition, they play an important role in controlling contamination within systems. The lubricant works as a conduit in which it transports contaminants to filters to be removed. These fluids also aid in temperature control by absorbing heat from surfaces and transferring it to a point of lower temperature where it can be dissipated.

There are three different types of lubrication: boundary, mixed and full film. Each type is different, but they all rely on a lubricant and the additives within the oils to protect against wear.

Full-film lubrication can be broken down into two forms: hydrodynamic and elastohydrodynamic. Hydrodynamic lubrication occurs when two surfaces in sliding motion (relative to each other) are fully separated by a film of fluid. Elastohydrodynamic lubrication is similar but occurs when the surfaces are in a rolling motion (relative to each other). The film layer in elastohydrodynamic conditions is much thinner than that of hydrodynamic lubrication, and the pressure on the film is greater. It is called elastohydrodynamic because the film elastically deforms the rolling surface to lubricate it.

Wes Cash, Noria Corporation

Tags: industrial lubricants, synthetic lubricants, greases

Lubrication is a word that’s often used in regards to machinery reliability and maintenance, but what is lubrication? The dictionary defines lubrication as the application of some oily or greasy substance in order to diminish friction. Although this is a valid definition, it fails to realize all that lubrication actually achieves.

Lubrication is a word that’s often used in regards to machinery reliability and maintenance, but what is lubrication? The dictionary defines lubrication as the application of some oily or greasy substance in order to diminish friction. Although this is a valid definition, it fails to realize all that lubrication actually achieves.

Many different substances can be used to lubricate a surface. Oil and grease are the most common. Grease is composed of oil and a thickening agent to obtain its consistency, while the oil is what actually lubricates. Oils can be synthetic, vegetable or mineral-based as well as a combination of these. The application determines which oil, commonly referred to as the base oil, should be used. In extreme conditions, synthetic oils can be beneficial. Where the environment is of concern, vegetable base oils may be utilized.

Lubricants containing oil have additives that enhance, add or suppress properties within the base oil. The amount of additives depends on the type of oil and the application for which it will be used. For instance, engine oil might have a dispersant added. A dispersant keeps insoluble matter conglomerated together to be removed by the filter upon circulation. In environments that undergo extremes in temperature, from cold to hot, a viscosity index (VI) improver may be added. These additives are long organic molecules that stay bunched together in cold conditions and unravel in hotter environments. This process changes the oil’s viscosity and allows it to flow better in cold conditions while still maintaining its high-temperature properties. The only problem with additives is that they can be depleted, and in order to restore them back to sufficient levels, generally the oil volume must be replaced.

Reducing friction is a key objective of lubrication, but there are many other benefits of this process. Lubricating films can help prevent corrosion by protecting the surface from water and other corrosive substances. In addition, they play an important role in controlling contamination within systems. The lubricant works as a conduit in which it transports contaminants to filters to be removed. These fluids also aid in temperature control by absorbing heat from surfaces and transferring it to a point of lower temperature where it can be dissipated.

Reducing friction is a key objective of lubrication, but there are many other benefits of this process. Lubricating films can help prevent corrosion by protecting the surface from water and other corrosive substances. In addition, they play an important role in controlling contamination within systems. The lubricant works as a conduit in which it transports contaminants to filters to be removed. These fluids also aid in temperature control by absorbing heat from surfaces and transferring it to a point of lower temperature where it can be dissipated.

There are three different types of lubrication: boundary, mixed and full film. Each type is different, but they all rely on a lubricant and the additives within the oils to protect against wear.

Full-film lubrication can be broken down into two forms: hydrodynamic and elastohydrodynamic. Hydrodynamic lubrication occurs when two surfaces in sliding motion (relative to each other) are fully separated by a film of fluid. Elastohydrodynamic lubrication is similar but occurs when the surfaces are in a rolling motion (relative to each other). The film layer in elastohydrodynamic conditions is much thinner than that of hydrodynamic lubrication, and the pressure on the film is greater. It is called elastohydrodynamic because the film elastically deforms the rolling surface to lubricate it.

WordPress Tags: Lubrication,word,machinery,maintenance,dictionary,substance,friction,Although,definition,Many,Grease,agent,consistency,mineral,combination,Where,environment,substances,vegetable