New Dominator® Coolant Boost

Effective Heat Transfer, Enhanced Corrosion Protection

Buy Dominator Coolant Boost here, for $8.35/bottle. Discounts if you are a Preferred Customer

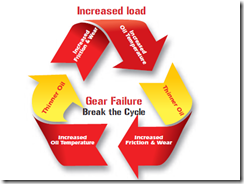

Racers demand lower engine operating temperatures in order to achieve maximum efficiency and horsepower on the track, while the straight water coolant used by many racers opens engines up to damaging radiator and water pump corrosion. New AMSOIL Dominator® Coolant Boost (RDCB) provides racers and motorists with significantly lower engine operating temperatures, quicker engine warm-up times and advanced corrosion protection.

Dominator Coolant Boost is formulated with proprietary tiered surfactant technology, providing quick and effective heat transfer inside radiator and cylinder heads, which results in reduced operating temperatures, more efficient operation, increased horsepower and significantly reduced engine warm-up times in cold weather. Coolant Boost also contains a robust mixture of corrosion inhibitors that protect the radiator, heater core, water pump, cylinder heads, engine block and intake manifold from the damaging effects of corrosion.

Temperature Reduction Dynamometer Test

To test the temperature reduction capabilities of Dominator Coolant Boost, dyno tests were performed on a Chevy 350 cubic inch engine with an aluminum block and cylinder heads. Running the test with both straight water and water treated with Coolant Boost, the engine was operated at 4,500 rpm until coolant temperature stabilized.

Coolant Mixture Temperature

Straight Water 221°F

Water with Coolant Boost 202°F

Test results show water treated with Coolant Boost provided a 19°F temperature reduction.

Aluminum Corrosion Test

The Aluminum Corrosion Test (ASTM D-4340) measures the corrosion protection properties of Dominator Coolant Boost in modern automobile and high-performance race engines with aluminum cylinder heads. A cast aluminum puck was heated to 275°F at 28 PSI and exposed to the test coolant mixture for one week. Weight loss of less than 1.0 mg is required to pass the test.

Coolant Mixture Weight Loss

Straight Water 3.97 mg/cm2/wk

Water with Coolant Boost 0.14 mg/cm2/wk

Test results show water treated with Coolant Boost easily passed the Aluminum Corrosion Test.

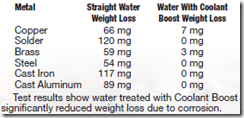

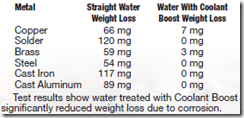

Metal Corrosion Test

The Metal Corrosion Test (ASTM D-2570) measures corrosion protection properties in automotive cooling systems. Using ASTM corrosive water designed to simulate hard and corrosive water in degraded coolant, six metal coupons constructed of the most common metals in automotive cooling systems were exposed to the test coolant mixture at 190°F. The coolant was maintained at a temperature and flow rate equivalent to the operating conditions seen in most passenger vehicles. Corrosive weight loss suffered during the test determines the additive’s corrosion protection properties.

Retail $11.10 per 16 oz Bottle

Racers demand lower engine operating temperatures in order to achieve maximum efficiency and horsepower on the track, while the straight water coolant used by many racers opens engines up to damaging radiator and water pump corrosion. AMSOIL Dominator® Coolant Boost (RDCB) provides racers and motorists with significantly lower engine operating temperatures, quicker engine warm-up times and advanced corrosion protection.

Dominator Coolant Boost is formulated with proprietary tiered surfactant technology, providing quick and effective heat transfer inside radiators and cylinder heads, which results in reduced operating temperatures, more efficient operation, increased horsepower and significantly reduced engine warm-up times in cold weather. Coolant Boost also contains a robust mixture of corrosion inhibitors that protect the radiator, heater core, water pump, cylinder heads, engine block and intake manifold from the damaging effects of corrosion.

Temperature Reduction Dynamometer Test

To test the temperature reduction capabilities of Dominator Coolant Boost, dyno tests were performed on a Chevy 350 cubic inch engine with an aluminum block and cylinder heads. Running the test with both straight water and water treated with Coolant Boost, the engine was operated at 4,500 rpm until coolant temperature stabilized.

| COOLANT MIXTURE |

STABILIZED COOLANT TEMPERATURE |

|

Straight Water

|

221°F

|

|

Water with Coolant Boost

|

202°F

|

Test results show water treated with Coolant Boost provided a 19°F temperature reduction.

Aluminum Corrosion Test

The Aluminum Corrosion Test (ASTM D-4340) measures the corrosion protection properties of Dominator Coolant Boost in modern automobile and high-performance race engines with aluminum cylinder heads. A cast aluminum puck was heated to 275°F at 28 PSI and exposed to the test coolant mixture for one week. Weight loss of less than 1.0 mg is required to pass the test.

| COOLANT MIXTURE |

WEIGHT LOSS |

| Straight Water |

3.97 mg/cm2/wk |

| Water with Coolant Boost |

0.14 mg/cm2/wk |

Test results show water treated with Coolant Boost easily passed the Aluminum Corrosion Test.

Metal Corrosion Test

The Metal Corrosion Test (ASTM D-2570) measures corrosion protection properties in automotive cooling systems. Using ASTM corrosive water designed to simulate hard and corrosive water in degraded coolant, six metal coupons constructed of the most common metals in automotive cooling systems were exposed to the test coolant mixture at 190°F. The coolant was maintained at a temperature and flow rate equivalent to the operating conditions seen in most passenger vehicles. Corrosive weight loss suffered during the test determines the additive’s corrosion protection properties.

| METAL |

STRAIGHT WATER

WEIGHT LOSS |

WATER WITH COOLANT BOOST

WEIGHT LOSS |

| Copper |

66mg |

7mg |

| Solder |

120mg |

0mg |

| Brass |

59mg |

3mg |

| Steel |

54mg |

0mg |

| Cast Iron |

117mg |

0mg |

| Cast Aluminum |

89mg |

0mg |

Test results show water treated with Coolant Boost significantly reduced weight loss due to corrosion.

Recommendations

Dominator Coolant Boost is recommended with both racing applications using straight water coolant and automotive applications using 50/50 coolant/water mixtures.

Directions: With engine off and cool, make sure cooling system is filled with selected coolant. Shake bottle and pour calculated amount of Coolant Boost into radiator. Start engine, turn heat on high and run for 15 minutes. Do NOT use distilled water unless mixed with 50% antifreeze.

Dosage: For straight water applications, add 2 fl. oz. of Coolant Boost per quart of tap or softened water. For 50/50 coolant/water applications, add 1 fl . oz. of Coolant Boost per quart of 50/50 mix.

Frequency: In applications using Coolant Boost with straight water, drain and re-fill the coolant system and add Coolant Boost once per year or when indicated by color change. A distinctive pH color change indicates when the pH has fallen to a point where corrosion can set in. When the Coolant Boost/water mixture changes from pink to clear, another dosage of Coolant Boost should be added. Monitoring the pH level will ensure all vital areas of the cooling system are protected against corrosion.

In applications using Coolant Boost with 50/50 coolant/water mixtures, add Coolant Boost once per year or every 30,000 miles, whichever comes first. Follow coolant manufacturer recommendations for coolant change intervals.